New Boiler Cost 2026: What Homeowners Really Pay

Discover typical installed costs for a new boiler in 2026, including boiler type ranges, installation factors, and money-saving tips from Boiler Hub.

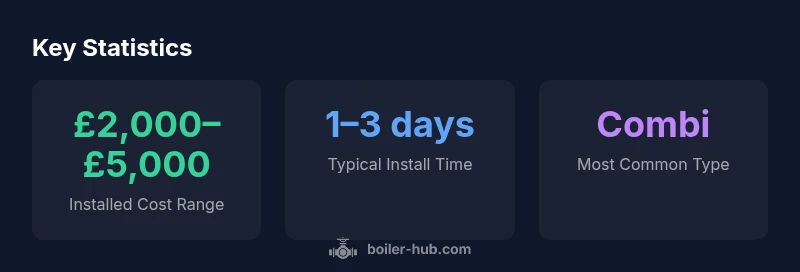

A typical installed cost for a new boiler in 2026 ranges from £2,000 to £5,000, depending on boiler type, home size, and installation complexity. This broad band reflects combi, system, and regular boilers, plus regional labor rates and venting needs. The Boiler Hub Analysis, 2026, notes that most homes fall within this range, with higher-end models and complex retrofits pushing toward the top end.

How to interpret boiler cost: what drives the price

When homeowners ask how much does a new boiler cost, the answer depends on several intertwined factors. The headline cost is the boiler unit itself, but the installation, location, and required upgrades can add substantial sums. According to Boiler Hub Analysis, 2026, the installed price for a typical modern boiler sits in a broad band: roughly £2,000 to £5,000, with wide variation based on your home’s size and the chosen model. Understanding where that variation comes from helps you avoid sticker shock and plan a realistic budget.

Key cost drivers include the boiler type (combi, system, or conventional), the efficiency rating (A-rated units typically cost more up front but save on energy bills), and the complexity of installation. If the boiler is being relocated, a chimney flue modification, or additional venting is required, expect higher labor charges. Accessibility in the boiler cupboard, need for additional radiators, or upgrades to gas supply lines can push the price upward. Labour rates vary by region; cities with high demand typically command higher rates. Finally, warranties and aftercare plans contribute to the total, with longer coverage offering peace of mind but adding to upfront costs.

Boiler Hub notes that homeowners should frame their budget with a range rather than a fixed figure, because small decisions—such as adding smart controls or choosing a premium condensing unit—can move the total price noticeably.

Boiler types and their rough cost bands

For most homes, three boiler types cover the majority of installations: combi (combination) boilers, system boilers, and regular (heat-only) boilers. Each type has its pros, cons, and price implications. Combi boilers are typically compact and well-suited for smaller homes with limited space and moderate hot-water demand. System boilers offer a balance of efficiency and performance for medium to larger homes, often paired with a domestic hot water cylinder. Regular boilers cater to older properties with existing storage tanks and can support higher hot-water volumes but usually require more hardware and pipework.

Installed cost bands differ based on the chosen model and ancillary components (such as expansion vessels, pumps, and controls). A combi boiler replacement may sit toward the lower end of the spectrum if the existing flue and pipework require minimal modification. In contrast, a system or regular boiler with a new cylinder, upgraded pumps, and additional controls can push the total toward the upper end. When budgeting, remember to factor in the cost of controls (thermostats and smart devices) which can add a few hundred pounds.

Across all types, ensure quotes include removal of the old unit and proper disposal; if not, that will be a separate line item that increases the overall price.

Hidden costs that often surprise homeowners

Even well-planned projects can have hidden costs. If your installation requires a new flue, condensate drainage, or venting, you’ll see additional charges for materials and labor. Tight boiler cupboards or difficult access can demand specialized tools and longer labor hours, adding to the bill. Upgrading gas supply lines, upgrading radiators, or adding new controls can also impact the final price. Don’t forget disposal fees for the old boiler, which are frequently billed separately. Finally, ensure you have a contingency in your budget for unexpected issues discovered during installation, such as old pipework needing upgrading to meet current safety standards. A transparent quote should spell out every item, so there are no surprises at the end.

To keep surprises to a minimum, request a full breakdown and ask installers to itemize excluding and including items clearly, so you can compare like-for-like across quotes.

Regional and contractor factors that move the price

Prices for boiler installation vary by region due to labor markets, demand, and regulatory requirements. In areas with skilled labor shortages or high demand, installation rates may be higher. Some quotes also reflect regional permit fees, safety inspections, or waste disposal charges. Always confirm whether the quoted price includes VAT, travel, and potential scaffolding or access equipment. A reputable installer will walk you through regional considerations during the initial survey and explain how they influence the overall cost. Additionally, the cost of materials such as flue extensions, radiator upgrades, or smart controls can differ by supplier, contributing to regional price variation. Being aware of these factors helps you set accurate expectations and avoid surprises when you receive the final invoice.

How to estimate your total installed price step by step

Estimating the total installed price involves a clear, repeatable process. Start with your core needs: decide on boiler type and efficiency level. Gather at least three written quotes, and ensure each quote covers the same inclusions for a fair comparison. Confirm whether there’s removal and disposal of the old boiler and whether any additional work—like flue relocation, gas-line upgrades, or radiator additions—is necessary. Ask for a detailed line-by-line breakdown, so you can see how much is allocated to the boiler unit, installation labor, and any ancillary items such as controls or new valves. Finally, discuss timing and potential delays, plus a contingency cushion (commonly 5–10%) for unexpected issues.

From there, you’ll be in a position to compare quotes on a like-for-like basis and choose the option that offers the best balance of upfront price, reliability, and long-term value.

Financing, warranties, and maintenance considerations

A new boiler is a major purchase, but there are ways to manage the cost. Look at financing options offered by lenders or installers, including monthly payment plans that spread the cost over time. Compare warranty lengths and coverage areas; longer warranties can provide peace of mind but may increase upfront prices. Maintenance contracts can help prevent expensive breakdowns by scheduling regular service visits and ensuring the boiler operates at peak efficiency. When evaluating offers, ask whether the price includes a planned annual service, parts coverage, and what the cover excludes. Financing and warranty choices should align with your long-term cost savings and risk tolerance, so you can protect your investment over the boiler’s expected life.

Energy efficiency and future savings

Energy efficiency is a major factor in long-term running costs. Higher-efficiency boilers can reduce annual energy use, and many models qualify for best-in-class efficiency ratings. While the upfront cost is higher, payback can be achieved through lower energy bills, improved reliability, and fewer repairs. When comparing models, scrutinize efficiency ratings (such as SAP or ERP values where relevant) and whether the boiler complies with current standards. Upgrading to a high-efficiency boiler may also enable better compatibility with smart thermostats and zoning controls, enabling more precise, cost-effective heating management. The potential for energy savings should be weighed against the incremental upfront price to determine the total cost of ownership over the expected life of the boiler.

When to replace vs repair and planning ahead

Boiler reliability tends to decline with age, and a heavy repair bill can be a signal that replacement is more cost-effective in the long run. Typical lifespans vary by type and usage, but most boilers reach peak efficiency during their first several years and gradually lose efficiency over time. If maintenance demands rise or repair costs climb beyond a reasonable threshold, replacement may be the smarter financial decision. Planning ahead—tracking the boiler’s age, service history, and the condition of linked components like radiators and pumps—helps you avoid emergency installs and enables you to schedule replacements during favorable market windows. Early budgeting for a replacement, especially before peak winter demand, can also reduce overall installation costs.

Getting quotes: questions to ask installers

To ensure you’re comparing apples to apples, ask installers the following questions: Which boiler type do you recommend for my home and why? What exactly is included in the price (removal, disposal, new pipes, venting, and controls)? Will there be additional charges for permit fees, scaffolding, or travel? How long will the installation take, and what are the potential downtime implications? Do you offer a warranty, and what does it cover? Are there financing options or maintenance contracts available? Getting clear answers to these questions helps you choose a reliable installer and avoid surprise costs.

Typical installed boiler cost ranges by type

| Boiler Type | Estimated Installed Cost Range | Notes |

|---|---|---|

| Combi boiler | £2,000–£4,000 | Compact, space-saving, lower hot-water reserve |

| System boiler | £3,000–£5,000 | Cylinders, higher hot-water capacity |

| Regular boiler | £3,500–£6,000 | Best for older homes with existing tanks |

| Notes | Quotes should include removal and disposal; check for extra costs like venting upgrades |

Questions & Answers

What is the typical installed cost of a new boiler?

Typical installed costs vary by boiler type and home specifics, but a reasonable range is £2,000–£5,000. This includes the boiler unit, installation, and basic controls. Always request a full breakdown to confirm exactly what’s included.

Most homeowners see a price between two and five thousand pounds, depending on the boiler type and installation details.

Does installation pricing include removal of the old boiler?

Not automatically. Some quotes include removal and disposal of the old boiler, while others treat it as a separate charge. Always confirm this in writing and ensure disposal methods comply with local regulations.

Check whether the old boiler removal is included; if not, it will be an extra cost when you sign the contract.

How long does a boiler installation usually take?

Most installations take 1–3 days, depending on accessibility, venting requirements, and any needed gas-line upgrades. Complex retrofits or relocations can extend this window.

Usually one to three days, depending on the work required.

What factors influence the price of a new boiler?

Factors include boiler type, efficiency rating, existing pipework, flue changes, and whether extra radiators or controls are installed. Regional labor rates and permit fees also affect the total.

Price depends on boiler type, efficiency, and any extra work like venting or upgrading pipes.

Are there financing options for boiler replacement?

Many installers offer financing or monthly payment plans. Compare interest rates, terms, and whether the plan covers installation and maintenance.

There are financing options; compare plans to find one that fits your budget.

How can I reduce boiler costs without sacrificing reliability?

Shop around for quotes, choose a high-efficiency model with a good warranty, and consider phased upgrades (controls first, boiler later) if affordable. Regular maintenance can also prevent costly repairs.

Get several quotes, pick an efficient model with a solid warranty, and maintain regularly.

“Boiler costs reflect both equipment quality and installation complexity; planning for long-term energy savings can offset upfront expenses.”

Key Points

- Identify your boiler type to estimate costs.

- Expect a broad price range due to installation complexity.

- Get multiple quotes and check inclusions.

- Consider high-efficiency models to reduce long-term costs.

- Plan for ancillary costs like removal and controls.